These five ingenious materials from 2025 could make buildings greener

Construction materials are responsible for nearly one-third of global carbon dioxide emissions. And as global demand for construction continues to rise (it has already tripled over the past 25 years), its emissions are bound to climb even higher.e

In fact, some, like environmental engineer and University of Virginia professor Andres Clarens, see materials’ potential negative impact as so existential that he calls them the “last major frontier” in the fight against climate change. If that’s the case, we need to reduce the emissions associated with commonly used building materials like cement and steel—and we need to develop alternative materials that emit fewer greenhouse gas emissions by default. And we need to do it fast.

This year, material designers delivered. Some of these new materials are still in the testing phase, others are already on the market. All five have tremendous potential to make our buildings more sustainable.

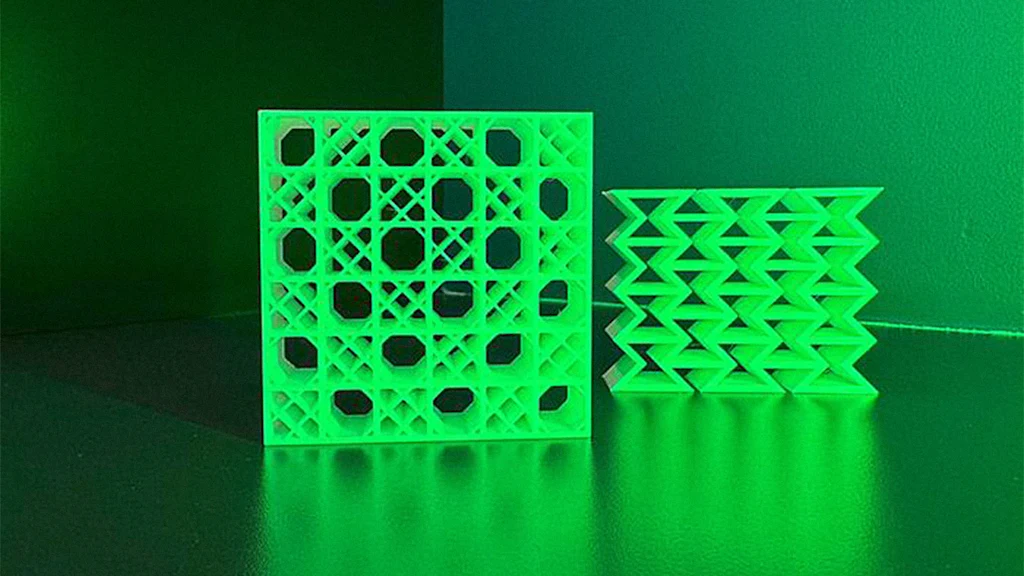

1. A superstrong material inspired by the deep-sea sponge

Earlier this year, researchers at the Royal Melbourne Institute of Technology invented a bio-inspired building material that is both lightweight and resilient under pressure, which could help reduce the use of steel and concrete. The key to their innovation? A little creature that lives thousands of meters deep in the ocean.

The deep-sea sponge’s lattice-like skeleton, which has been optimized over millions of years, can absorb force while maintaining its strength. According to the researchers, a similarly designed material could enable “thinner load-bearing walls and slimmer columns,” which in turn, would reduce the amount of steel and concrete required to achieve structural integrity.

The material is still in the testing phase.

2. A ‘Superwood’ that is stronger than steel

Seven years ago, scientists at the University of Maryland said they discovered a way to make wood so strong that it could compete with steel. This year, their research culminated in the launch of Superwood, a material that has 50% greater tensile strength than steel and a strength-to-weight ratio that’s 10 times better.

Superwood was developed by a spin-off startup called InventWood, which began mass-producing the material this summer. The company’s first facility in Frederick, Maryland, can produce one million square feet of Superwood per year, with applications varying from interior finishes to exterior-grade panels for siding and roofing.

The plan, according to InventWood cofounder Alex Lau, is to build “a larger facility that will scale to over 30 million square feet, enabling use in infrastructure and large developments.”

3. A cross-laminated timber made of fallen trees

By some estimates, cities lose a staggering 36 million trees a year to storms, insects, and disease. Over the past six years, the Washington, D.C.-based startup Carbon Cambium has salvaged six million board feet of wood from these fallen trees, diverting it from the landfill, and turning it into usable timber for furniture with companies like Room & Board and Sabai.

This year, the startup developed its first product for the construction industry. Carbon Smart Wood is the first cross-laminated timber (CLT) made from salvaged trees, which promises to make mass timber construction even more sustainable.

The company offers millwork like decking and flooring, and full CLT structural panels for buildings. Forty thousand linear feet of the material will appear on the facade of the new JFK Airport expansion in 2026.

4. A new take on rammed earth

Rammed earth, a building technique where damp soil is compacted in layers within temporary forms, has propped up buildings for millennia. This year, the humble material got an upgrade when researchers at the Royal Melbourne Institute of Technology encased it in a cardboard tube.

The resulting material, dubbed cardboard-confined rammed earth (CCRE), consists of rammed earth that’s been compacted inside cylindrical tubes. Typically, rammed earth walls also include a dose of cement to improve strength and durability, but the cardboard formwork in CCRE acts as a shell, negating the need for cement.

The researchers say the cardboard helps protect the rammed earth from surrounding environments, while additional treatment on the cardboard can extend its life as well. They have also developed a similar version using carbon-fiber tubes.

To date, the team has built a small-scale prototype, but if scaled, the material could be used to build low-rise and modular buildings with no cement.

5. A paint that changes colors with the seasons

We’ve known for a while now that painting surfaces like streets and roofs in white can make them cooler because white reflects heat—and painting them black can make them warmer because black absorbs heat.

This year, industrial designer Joe Doucet took this time-tested innovation to a new level by developing a “climate-adaptive” paint that can change colors based on the outside temperature.

The paint, which can be mixed with other tints (so you can still have your yellow house) could save an estimated 20–30% in energy costs every year. Doucet’s team is currently testing the final formula, with the goal of licensing it to paint manufacturers when ready.