Wilson’s airless basketball is back by popular demand

Wilson’s Airless Gen1 basketball is back. The hollow, $2,500 3D-printed basketball that doesn’t need to be inflated was first showcased at the 2023 NBA All-Star Weekend. Now, Wilson is selling the ball via a new production run for the remaining few people who can afford to spend thousands of dollars on a basketball. The Airless Gen1 ball features a latticed pattern of hexagonal holes and doesn’t require an inflated bladder inside. By all accounts of professional and amateur players who have tried the airless wonder, its honeycomb architecture and plastic material makes it perform like a traditional basketball, matching its size, weight, and rebound characteristics. [Photo: Wilson] The initial release in February 2024 sold out rapidly. Now, Wilson is responding to the high demand by rereleasing the basketball in limited quantities, said Kevin Murphy, general manager of team sports at Wilson, in a press release: “We have been consistently overwhelmed by the excitement surrounding our Airless basketball products.” The rerelease features three color options: black, natural/white, and a new burgundy. Each ball is produced using the same 3D-printing process as the original, with refinements implemented to enhance production. I asked Nadine Lippa, Wilson’s innovation manager, why the company hasn’t been able to ramp up production so more people can buy it. “We’re still using the same printer, we’re still using the same type of smoothing and dyeing,” she explained. The Airless Gen1’s high price tag reflects the fact that 3D technology is not mature enough to make the jump to industrial production. It’s not a problem of the design, but of how slow and cumbersome 3D-printing technology still is. Without a quicker way to materialize these items, which need extra cleaning and sanding work to turn them into consumer products, it can’t really command production runs sizable enough to knock off at least one zero from that price tag. [Photo: Wilson] 3D-printing technology for industrial production keeps advancing but still faces big challenges like slow scalability, material limitations, and complex post-processing and quality control. While the industry is not stagnant, it is not yet fully realized for mass production. “The additive and 3D-printing ecosystem continues to evolve year-over-year,” says Lippa, “and the Wilson Labs team continues to monitor the progress and engage with key players in the industry.” Lippa tells Fast Company that Wison is still committed to making this technology more accessible in the future. Her team is continuously assessing all options on how to bring this to scale in the best way possible. “Our mission is to create great high-performing products at every level for every athlete, so we will continue to research and explore until we solve the problem,” she says. “Specific to our Airless Basketball, we are continuing to evaluate 3D-printing materials and technologies that offer the right properties needed to make a basketball perform at a much-lower cost.” Hopefully, one day we’ll be able to pick up one at the store just like we do with normal basketballs. But until then, the Airless Gen1 will remain a big-ticket item and an unreachable object of desire for b-ball fans everywhere. Starting Thursday, February 13, the Wilson Airless Gen1 will be available for purchase from Wilson.com. A limited number of units will also be available at NBA All-Star 2025 in San Francisco on February 17. Thankfully, you may have a higher chance of getting lucky, according to Lippa. “While we don’t share exact quantities, this will be our largest drop of the Airless Gen1 to date.”

Wilson’s Airless Gen1 basketball is back. The hollow, $2,500 3D-printed basketball that doesn’t need to be inflated was first showcased at the 2023 NBA All-Star Weekend. Now, Wilson is selling the ball via a new production run for the remaining few people who can afford to spend thousands of dollars on a basketball.

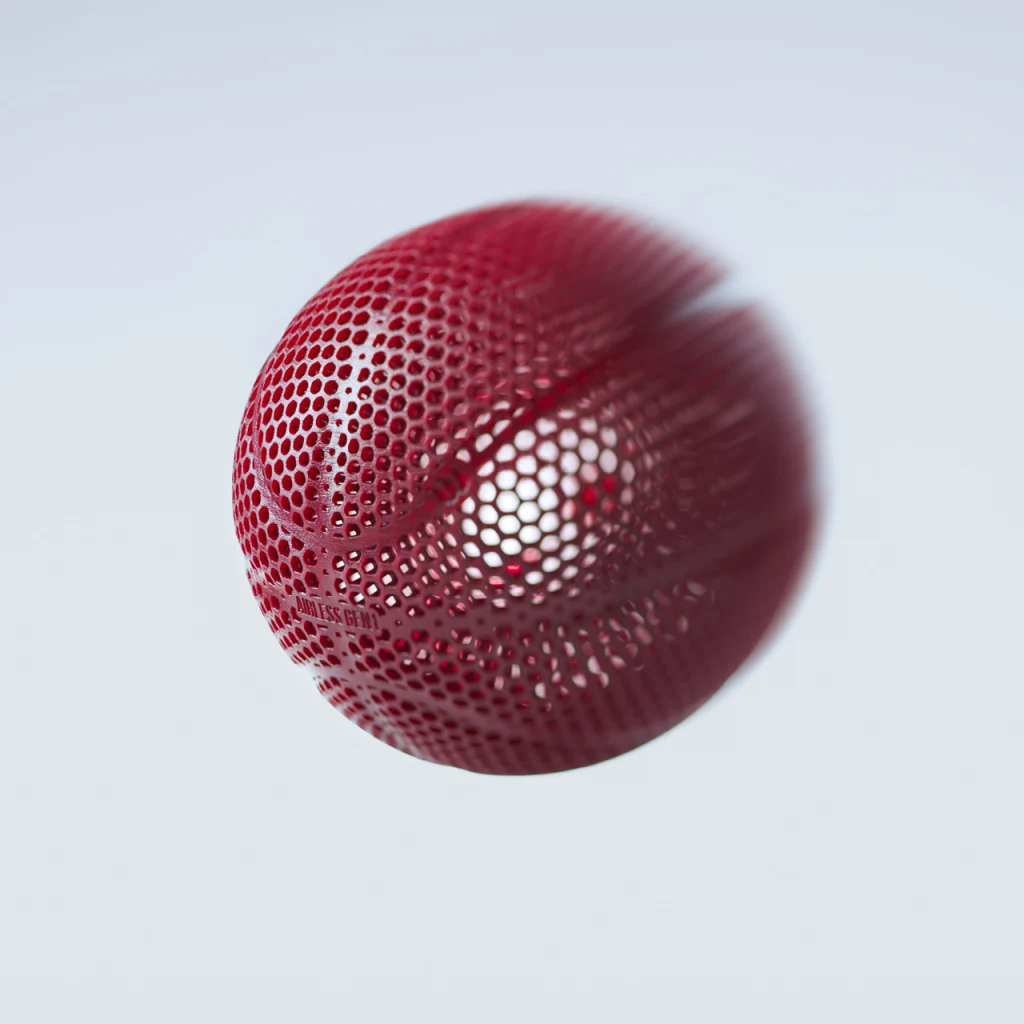

The Airless Gen1 ball features a latticed pattern of hexagonal holes and doesn’t require an inflated bladder inside. By all accounts of professional and amateur players who have tried the airless wonder, its honeycomb architecture and plastic material makes it perform like a traditional basketball, matching its size, weight, and rebound characteristics.

The initial release in February 2024 sold out rapidly. Now, Wilson is responding to the high demand by rereleasing the basketball in limited quantities, said Kevin Murphy, general manager of team sports at Wilson, in a press release: “We have been consistently overwhelmed by the excitement surrounding our Airless basketball products.” The rerelease features three color options: black, natural/white, and a new burgundy. Each ball is produced using the same 3D-printing process as the original, with refinements implemented to enhance production.

I asked Nadine Lippa, Wilson’s innovation manager, why the company hasn’t been able to ramp up production so more people can buy it. “We’re still using the same printer, we’re still using the same type of smoothing and dyeing,” she explained.

The Airless Gen1’s high price tag reflects the fact that 3D technology is not mature enough to make the jump to industrial production. It’s not a problem of the design, but of how slow and cumbersome 3D-printing technology still is. Without a quicker way to materialize these items, which need extra cleaning and sanding work to turn them into consumer products, it can’t really command production runs sizable enough to knock off at least one zero from that price tag.

3D-printing technology for industrial production keeps advancing but still faces big challenges like slow scalability, material limitations, and complex post-processing and quality control. While the industry is not stagnant, it is not yet fully realized for mass production. “The additive and 3D-printing ecosystem continues to evolve year-over-year,” says Lippa, “and the Wilson Labs team continues to monitor the progress and engage with key players in the industry.”

Lippa tells Fast Company that Wison is still committed to making this technology more accessible in the future. Her team is continuously assessing all options on how to bring this to scale in the best way possible. “Our mission is to create great high-performing products at every level for every athlete, so we will continue to research and explore until we solve the problem,” she says. “Specific to our Airless Basketball, we are continuing to evaluate 3D-printing materials and technologies that offer the right properties needed to make a basketball perform at a much-lower cost.”

Hopefully, one day we’ll be able to pick up one at the store just like we do with normal basketballs. But until then, the Airless Gen1 will remain a big-ticket item and an unreachable object of desire for b-ball fans everywhere.

Starting Thursday, February 13, the Wilson Airless Gen1 will be available for purchase from Wilson.com. A limited number of units will also be available at NBA All-Star 2025 in San Francisco on February 17. Thankfully, you may have a higher chance of getting lucky, according to Lippa. “While we don’t share exact quantities, this will be our largest drop of the Airless Gen1 to date.”