Jake Dyson has a vision for the future of his family’s $9.5 billion company

When Jake Dyson looks back at his childhood, he doesn’t remember his father, James, as the visionary founder of Dyson, the world-renowned technology brand. Instead, he recalls a tinkerer who was always working on something in the basement. “I watched Dad being a bit of a crazy inventor,” the younger Dyson says. “He was mucking about with potato peelers, amphibious vehicles, boat trolleys . . . all sorts of ideas on our doorstep.” James’s inventive streak paid off. In the late 1980s, after 15 years of experimentation and 5,127 prototypes, he developed a vacuum cleaner that was more powerful than others on the market because it used stronger motors and leveraged centrifugal forces to suck up more debris. In 1991, James launched Dyson to sell this patented vacuum. The machine was a phenomenon, becoming a popular product in homes all over the world. Over the past three decades, Dyson expanded into new categories of products, all of which generally focused on transferring air: hair dryers, fans, air purifiers, dehumidifiers. Today, Dyson is a titan in the consumer technology industry, generating $9.5 billion in global revenue and counting 14,000 employees across 80 countries. (Three months ago, Dyson laid off 1,000 employees in the U.K. and recently fired a dozen more in Singapore. CEO Hanno Kirner said this global restructuring has not impacted the pace of product launches, noting, “We know we always need to be entrepreneurial and agile.”) Jake surveyed his father’s success with admiration, but he chose to take his own path. Like his father, he was interested in inventing new products, but he was most interested in developing light fixtures. After graduating with a degree in product design from Central St. Martins arts college in London, he went on to launch his own business, Jake Dyson Products, which developed more powerful, longer-lasting LED lights. But a decade ago, he decided to join the family business and incorporate his products into the Dyson portfolio. James Dyson in 2018 [Photo: Christophe Archambault/AFP/Getty Images] Jake has spent years embedding himself in the company, working across many teams. But today, as chief engineer, he’s ready to take a bigger role in Dyson’s product development. He spearheaded the recent release of OnTrac, noise-canceling headphones that come in customizable colors. He also helped launch Dyson’s first-ever hair-styling products, which are made from chitosan, an ingredient in oyster mushrooms that locks in the structure of a hair strand during the drying process. These new product launches offer a glimpse into Jake’s vision for the family business and how he plans to bring these wide-ranging product categories under the same brand. We sat down with Jake to discuss what he imagines for Dyson’s future. This interview has been edited for length and clarity. [Photo: Dyson] I think many people were surprised when you launched headphones, because it seems very different from hair dryers and fans. What made you decide to go into audio? It’s quite straightforward actually. What we do at Dyson is research and scientific investigation. That enables us to join the dots in the technologies that we’ve become established in. Most of our products have a motor and fan to produce airflow. And over the last 30 years, a lot of that engineering work has been focused on reducing the noise. So we have lots of sound engineers who understand the electromechanical frequency of noise and vibration. We became acoustic experts. Hair dryers come very close to the ear, and we’ve been focused on making them quieter. Now that we’ve become very established in reducing sound, we were interested in looking at noise-canceling headphones. [Photo: Dyson] I was just at Sephora’s big beauty festival, where Dyson was promoting its latest hair-styling products. This also seemed like an unexpected direction for the brand. Why did you decide to launch hair care? We’ve been looking at human hair under a microscope for six years now to understand how to make our hair-care machines—and protect your hair. So the research team started to looking at novel ingredients on the market. That’s how they stumbled into chitosan, which allows you to better lock in styles. Our process is to do early research into an engineered product, and when we discover something interesting, we pursue it. As a company, we’re not bound to one product or category. We’re seduced into solving problems in other areas. If there’s a way we can leverage our technology to give people a new product, we’ll do it. [Photo: Dyson] The new headphones are very fashion-forward. And the new hair dryers you’ve created have a very interesting aesthetic. How do you think of the design of your products from a visual perspective? We want our products to be magical, not only in the way they work, but in the way they look. But from a design perspective, form always follows function. We want to design products

When Jake Dyson looks back at his childhood, he doesn’t remember his father, James, as the visionary founder of Dyson, the world-renowned technology brand. Instead, he recalls a tinkerer who was always working on something in the basement. “I watched Dad being a bit of a crazy inventor,” the younger Dyson says. “He was mucking about with potato peelers, amphibious vehicles, boat trolleys . . . all sorts of ideas on our doorstep.”

James’s inventive streak paid off. In the late 1980s, after 15 years of experimentation and 5,127 prototypes, he developed a vacuum cleaner that was more powerful than others on the market because it used stronger motors and leveraged centrifugal forces to suck up more debris. In 1991, James launched Dyson to sell this patented vacuum. The machine was a phenomenon, becoming a popular product in homes all over the world.

Over the past three decades, Dyson expanded into new categories of products, all of which generally focused on transferring air: hair dryers, fans, air purifiers, dehumidifiers. Today, Dyson is a titan in the consumer technology industry, generating $9.5 billion in global revenue and counting 14,000 employees across 80 countries. (Three months ago, Dyson laid off 1,000 employees in the U.K. and recently fired a dozen more in Singapore. CEO Hanno Kirner said this global restructuring has not impacted the pace of product launches, noting, “We know we always need to be entrepreneurial and agile.”)

Jake surveyed his father’s success with admiration, but he chose to take his own path. Like his father, he was interested in inventing new products, but he was most interested in developing light fixtures. After graduating with a degree in product design from Central St. Martins arts college in London, he went on to launch his own business, Jake Dyson Products, which developed more powerful, longer-lasting LED lights. But a decade ago, he decided to join the family business and incorporate his products into the Dyson portfolio.

Jake has spent years embedding himself in the company, working across many teams. But today, as chief engineer, he’s ready to take a bigger role in Dyson’s product development. He spearheaded the recent release of OnTrac, noise-canceling headphones that come in customizable colors. He also helped launch Dyson’s first-ever hair-styling products, which are made from chitosan, an ingredient in oyster mushrooms that locks in the structure of a hair strand during the drying process.

These new product launches offer a glimpse into Jake’s vision for the family business and how he plans to bring these wide-ranging product categories under the same brand. We sat down with Jake to discuss what he imagines for Dyson’s future.

This interview has been edited for length and clarity.

I think many people were surprised when you launched headphones, because it seems very different from hair dryers and fans. What made you decide to go into audio?

It’s quite straightforward actually. What we do at Dyson is research and scientific investigation. That enables us to join the dots in the technologies that we’ve become established in.

Most of our products have a motor and fan to produce airflow. And over the last 30 years, a lot of that engineering work has been focused on reducing the noise. So we have lots of sound engineers who understand the electromechanical frequency of noise and vibration. We became acoustic experts. Hair dryers come very close to the ear, and we’ve been focused on making them quieter. Now that we’ve become very established in reducing sound, we were interested in looking at noise-canceling headphones.

I was just at Sephora’s big beauty festival, where Dyson was promoting its latest hair-styling products. This also seemed like an unexpected direction for the brand. Why did you decide to launch hair care?

We’ve been looking at human hair under a microscope for six years now to understand how to make our hair-care machines—and protect your hair. So the research team started to looking at novel ingredients on the market. That’s how they stumbled into chitosan, which allows you to better lock in styles.

Our process is to do early research into an engineered product, and when we discover something interesting, we pursue it. As a company, we’re not bound to one product or category. We’re seduced into solving problems in other areas. If there’s a way we can leverage our technology to give people a new product, we’ll do it.

The new headphones are very fashion-forward. And the new hair dryers you’ve created have a very interesting aesthetic. How do you think of the design of your products from a visual perspective?

We want our products to be magical, not only in the way they work, but in the way they look. But from a design perspective, form always follows function. We want to design products that people are proud to own because they are beautiful, but the aesthetics are an afterthought. We always need to get the engineering behind the skin right first.

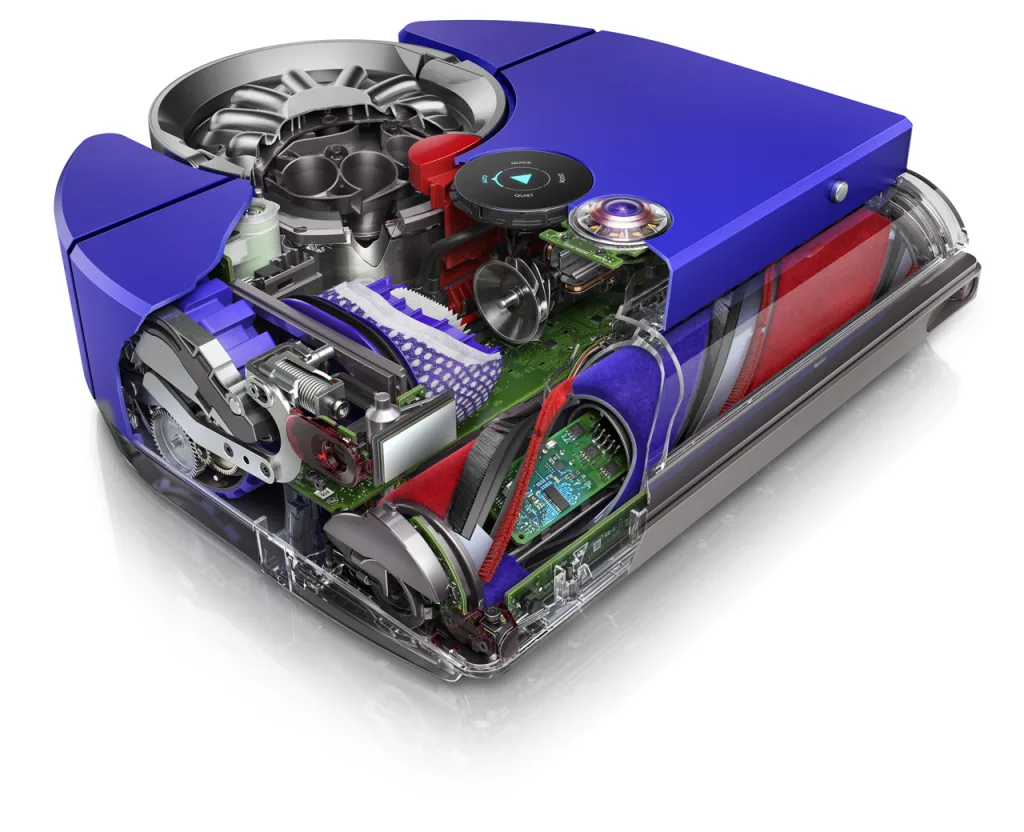

I will say that we are very focused on minimalism, which contributes to our aesthetic. There is barely a millimeter of space under the skin of a product. We use the least amount of plastic as possible; we make the product as compact, small, and lightweight as possible. The functionality is simplistic and pure. These are our core engineering principles, and you’ll see it across the aesthetics of all of our products.

How do you imagine all of these products fitting together in the Dyson universe?

From a business perspective, I think one of the most important things is to make the company more efficient in terms of handling the hundreds of millions of Dyson products that are out there in the market. How can we manage them, keep an eye on them, help the customer to service them?

I think this principle will help us to reshape the whole business model. We’re currently looking into connecting every product we make, by asking customers to connect them to an app. This allows us to see how many times the device has been turned on, how many times the motor has been run. We can do health checks on the device, without any human intervention.

This will have huge benefits for the consumer, but also for the company. In the future, we might be able to identify that a customer has been in the south of France for six months and hasn’t turned on their vacuum cleaner. We might extend their warranty for them. Or perhaps we send a customer a new hair dryer because based on our data, we can tell that their hair dryer is about to break.

We’re just starting this work. But we’re already seeing how it could unfold. AI will play a part in this, helping us see patterns and understand what products need attention.